Download

A letöltéshez add meg az email címed és mi elküldjük emailben a letöltő linket.

A letöltéshez add meg az email címed és mi elküldjük emailben a letöltő linket.

Having gone through hundreds of food safety audits, we think that the overcomplicated HACCP systems, which are indecipherable for the operators, do not serve any purpose and only cause damage. We have understood why training without practice is no good. We have revealed the serious shortcomings and mistakes hiding behind administrative compliance, and how they can put the future of business and the safety of consumers in jeopardy. So, we have decided to rethink everything. We have simplified the overcomplicated regulatory systems. We provide training combining theory and practice after knowledge assessment. The measures we propose after revealing the shortcomings during the audit are based on our experience gained, from operation practice.

According to our surveys, 4 out of 10 concerned managers read their own HACCP handbooks but 0 out of 10 could actually list all the critical points. Therefore, the current HACCP systems do not or just partly serve their regulatory purpose. For many business owners HACCP means no more than additional paperwork.

Reasons why:

Handbooks are complicated for the sake of being complicated; they contain commonplaces and business owners do not get clear instructions or training as to how to use them. HACCP systems to serve their real regulatory purpose and not just be present on an administrative level in operation, we must ‘reconstruct’ them, by focusing on their intended purpose: reaching a real and controlled food safety level.

Every regulation is worth as much as the extent to which people actually keep it. An HACCP regulation only makes sense if:

That is why we do not introduce systems following a phone-based assessment. The HACCP or self-review system is handed over after the establishment, on site and after detailed discussion of the control points.

Pursuant to the decree entering into force on 1 January 2018, all food business owners are required to introduce and operate a self-review system. The aim of self-review is for the business owner to be able to assess and certify his/her food safety procedures with objective methods.

We always create self-review plans individually and after on-site consultation and inspection so:

Pursuant to the self-review decree, the business may sign a contract with the National Food Chain Safety Office. The authority receives the self-review logs of those units which have given their consent to data transfer. Data provision is done through the authority’s digital channel called ONIR (pursuant to the strategic cooperation deal signed on 28 May 2020).

The pandemic caused a massive trust deficit in the target public especially when it comes to places and services where a lot of people gather in small, confined places.

This is exactly why it is crucial for the HORECA sector’s economic profitability and survival to strengthen the consumers’ trust.

The certification programme assures the customer of a uniform and safe operation throughout the entirety of the hospitality sector, which abates the fear of spending time in public and social places, and restores customer confidence.

Certification fee

Certification fee

The first certification is free of charge. Only the lab material costs (HUF 5000-10000) and the call-out fee must be paid.

Short description of our certification programme:

Aim, requirements, validity, level of certification.

The handbook helps you prepare for safe re-opening as well as for operation during the pandemic.

The checklist contains all the aspects we check during the certification programme.

Instead of pushing material knowledge, our training programme aims to emphasise practice where we shed light on causal relationships and take a practical, step-by-step approach in teaching good hygienic practices, which we might even teach on a position-by-position basis.

Training process

Topics

Our online-training website will be launched in September 2020 where tutorial videos will be available free of charge and on a position or process basis, helping employees learn about the safe steps of the respective working process. As a result, the employee may learn the necessary practical knowledge before starting to work. Thanks to the knowledge test, you can check how prepared your employees are from a practical and a theoretical point of view. Participation in the sessions is recorded with the help of attendance sheets. If someone passes an exam, they will get a certificate containing their name.

Planned courses

(1) 360-degree Food safety audit

The aim of the audit is to provide a comprehensive assessment of the food safety situation and level taking all parameters into account. Our inspection processes and assessment system are standardised, making them easily comparable with industrial practices. The assessment aspects contain the statutory minimum requirements (authority checklists), the necessary and recommended operation requirements and practices based on the principle of proportionality. The assessment matrix determines the food safety level and certification of the unit by weighting these aspects during the assessment.

(2) Self-review audit

We mainly check the compliance of processes and internal regulations during the audit using objective methods (measurements and samplings). We check product tracking, specialised storage and the efficiency of critical point inspections. With measuring devices, we also check such points which are out of the control scope so we can find potential weakness in food safety system.

(3) Cleaning audit

The hygienic compliance of surfaces (kitchen area, guest area, public places, rooms, consumer tools) is essential in determining the unit’s safety level. During the audit, we carry out inspections that are capable of detecting even microbiological or chemical residues. We check the cleaning and disinfecting instructions and how they are implemented.

(4) Supplier audit

We compiled the supplier assessment checklists by taking the buyer’s interest into consideration. We pay special attention to personal hygiene, the microbiological examination of raw materials, semi-finished goods and finished goods, and to product storage and shipping conditions. The result is a risk factor number which expresses the extent of risk of cooperation.

(5) COVID-19 CONTROL

The aim of our certification programme is to measure the fulfilment of all criteria in the operation that the National Public Health Center (NNK), the National Food Chain Safety Office (NÉBIH) and the World Health Organization require. The recommendations of the major domestic sectoral organisations, such as those of the Hungarian Tourism Agency (MTÜ) and the Hungarian Hotel & Restaurant Association (MSZÉSZ) have also been taken into account. During the certification process, we test for COVID-19 and check the disinfection efficiency of surfaces and consumer tools.

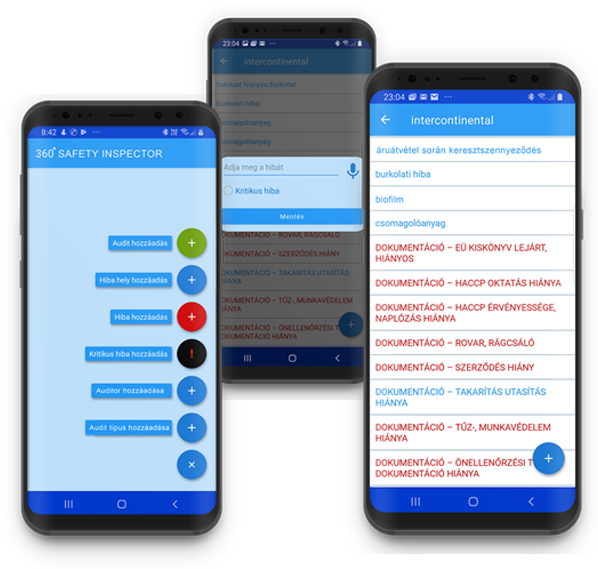

Advantages of the Safety Inspector audit app developed by us:

Advantages of the eCleaning certification system we developed ourselves:

Problem space

When ordering lab services, the lab service provider requires the customer to precisely determine the subject and purpose of the inspection. Therefore, customers must know what pathogens may be present at different phases of operation and with what probability so that they can specify what lab tests to run. This, however, is an unrealistic expectation.

The dispatched samplers are typically not prepared to have an overall picture of the risk factors and relationships of hazards caused by hotels, restaurants, manufacturing processes, used raw materials or building design.

Consequently, the collected samples may not be suitable for adequate representation of the microbiological safety level of the respective unit.

Solution

During the audits, we have the opportunity to shed light on the points where we can assume that either the infrastructure or the practice makes an inspection necessary. In this way, the customer will not get a representative picture from the sampling, but the interpretation of the results with suggestions for action.

Pathogen-specific tests

|

|

Allergen tests

|

|

The last element of our FOODWILL concept is process monitoring. For this purpose, we developed target systems that can monitor the entirety of the operation process in a verified and efficient way, at any time, even remotely.

Faster administrative processes

Time spent doing paperwork can be reduced by up to 80%.

Guaranteed control at critical points

By mandatory photo-taking at checkpoints, it can be ensured that processes are not just administered but actually controlled.

More authentic administration

Time stamps, coordinate marking, photo uploads and digital signature all make for a more authentic documentation.

Monitoring system

Our system keeps monitoring the logged values. It sends a warning if a check has been missed; it alerts the responsible manager if values are critical and also makes suggestions as to how to proceed.

Task traceability

The tasks arising from monitoring the unit can be assigned to a user within the unit, but an e-mail can be sent outside the unit too. Deadlines can be assigned to tasks which our system monitors and it sends a notification if a task has been performed or missed.

Cooling signal transmitter

We developed our own cooling temperature transmitter which does not require the redesign or installation of costly cooling equipment. Our wireless transmitters can be simple to set up, fast and cost-effective; their quantity can be grown flexibly. Critical values of temperature monitoring are sent as text message, e-mail or push message.

QR-code-based product tracking system

Product labelling is a major administrative burden for all businesses. The QR-code-based tracking module of the ONIR system was developed to ease this burden. The device can print the product labels with the necessary information by just one click after connecting with a wireless QR-code printer.

Process control

Our system represents the processes by adapting to the special requirements of a unit starting with the administration of cleaning tasks finished to supervision, to the customer’s certificate of completion.

System features

Automated functions

Task management

More authentic administration

Time stamp, coordinate marking, photo upload and digital signature render documentation more authentic.

Reviewed audit at the push of a button

By using the Safety Inspector, we set out to do no less than to implement an automatic reporting system without the need to edit in such a way that it can be incorporated into a standardised reporting system (by means of labelling). Technically it means that the system generates a certified report after closing the audit, which used to take hours to edit. This way, it can notify the concerned party in real time about the report results.